You are here:home > All Product > Pruduct's Detail

Lifting chain production process

Lifting chain is a common tool for lifting goods, lifting chain production process is more complex, there are many links, the following to explain the lifting chain production process in detail, I hope to help you:

Lifting chain production process

First, raw material inspection:

Lifting chain manufacturers to purchase a batch of raw materials into the factory, the need for staff to cut 10 cm of raw materials for hardness testing, spectral testing, etc., analysis of chemical elements is not in line with the standard, and then the workers with the naked eye to see the quality of raw materials, qualified to begin production;

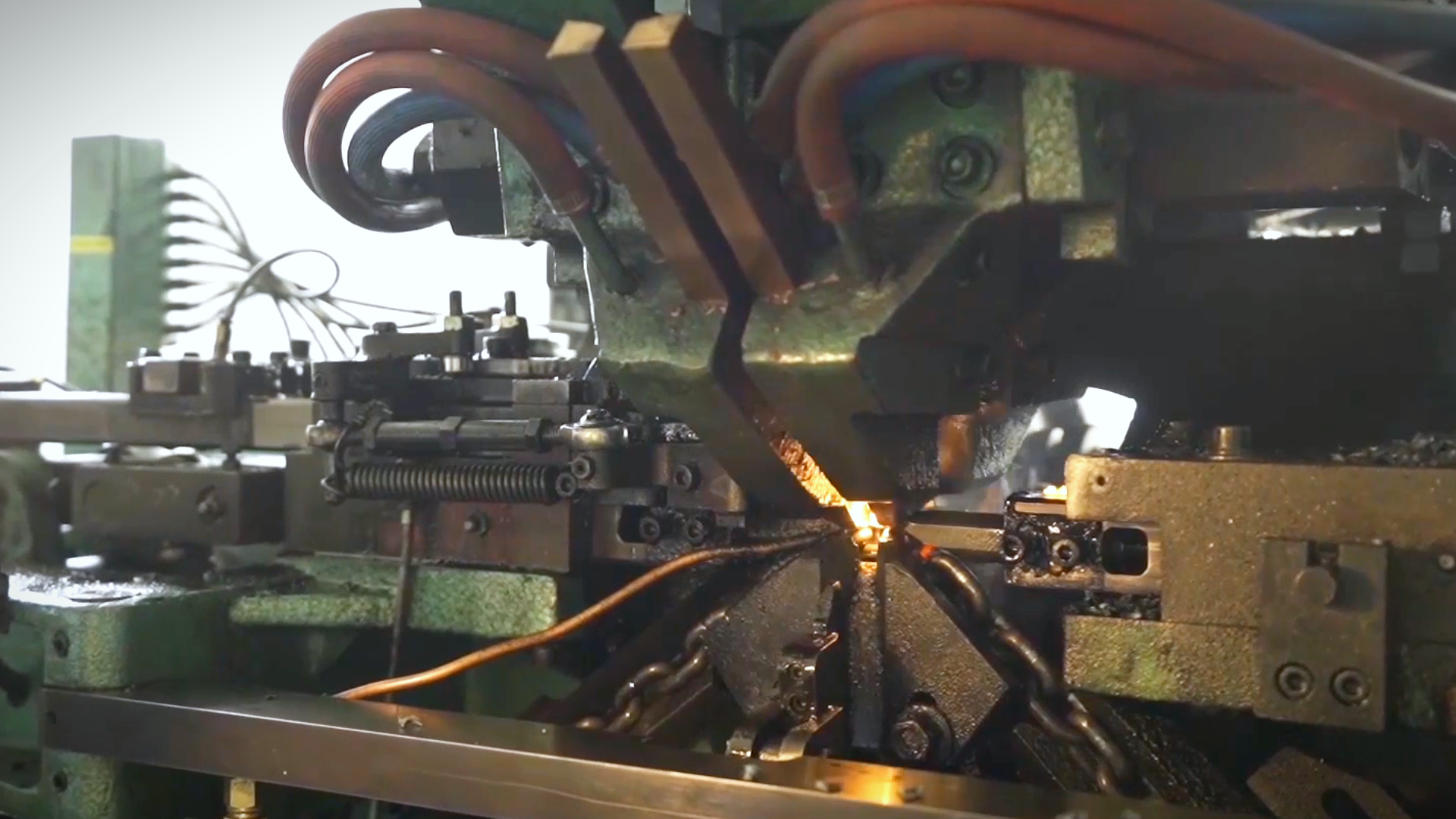

Second, welding production line:

It is necessary to produce according to the needs of customers, the chain braid welding machine is used to braid the chain, and then the fire welding machine is used to weld the chain, so that the surface of the mining chain is smooth, and a breaking test will be carried out in this link to test the tensile load of the chain;

Third, the first proofreading process:

Blackened lifting chain needs to be corrected once, in this link to confirm that the chain link is in line with the standard, the purpose of correction is to make steel marks, do identification, according to customer needs to do identification, this steel mark must be clearly visible;

Fourth, heat treatment process:

Galvanized lifting chain needs heat treatment, that is, we often say quenching, is operated under double frequency conversion, constant temperature control, heat treatment process is to improve the hardness and toughness of the lifting chain, and then need to cut a chain surface hardness, breaking tension, extension force test, see if it is in line with the standard;

Fifth, the second proofreading process:

The ring lifting chain needs to be corrected twice, cut 5 rings or 7 rings for correction, the tension is required to be greater than 2.5 times the rated load, and the chain size should meet the customer’s requirements;

Six, bow test:

Pull 6 meters of manganese steel lifting chain each time, with 2.5 times the rated load for bow test, so the purpose is to test the consistency of 6 meters lifting chain, this link can test the effect of heat treatment;

Seven, cutting:

According to customer requirements for a certain size of cutting, such as 6 meters, 10 meters, 20 meters, etc., in this link also need to carry out a chain breaking test;

Eight, surface treatment:

After cutting the high temperature lifting chain, the surface treatment process needs to be carried out according to the requirements of customers, including polishing, blackening, galvanizing, electrophoresis, dacromet and other surface treatment processes, so the purpose of surface treatment is to prevent rust, and customers need to choose the appropriate surface treatment process according to the use environment;

Nine, finished product inspection:

Lifting chain after the completion of the finished product, but also need quality inspection department inspection work, in this link need to test the lifting chain hardness, tension, breaking, elongation and other tests to see if it is in line with the standard;

Ten, packing and warehousing:

After passing the inspection of the lifting chain, it needs to be packed into the warehouse. You can choose tons of bags, wooden cases, iron drums, plastic drums and other packaging lifting chains.

In general, the lifting chain production process is more complex, each link needs to be strictly tested to ensure that the quality of the chain meets the requirements, “TOYO-INTL” manufacturers produce various specifications of the lifting chain, can meet the requirements of different environments.

In general, the lifting chain production process is more complex, each link needs to be strictly tested to ensure that the quality of the chain meets the requirements, “TOYO-INTL” manufacturers produce various specifications of the lifting chain, can meet the requirements of different environments.

Tags: bearing swivel hook,BINDER CHAIN GRADE70,CHAIN AW,chain block,CHAIN BLOCK CK,CHAIN BLOCK VD,CHAIN BLOCK VT,Chain Hoist,CHAIN SLING,DOWN CHAIN G80,ELECTRIC CHAIN HOIST,ELECTRIC CHAIN HOIST KD,ELECTRIC CHAIN HOIST TD,ELECTRIC WIRE ROPE HOIST SH,MINI ELECTRIC WIRE ROPE HOIST PA,MINI ELECTRICCHAIN HOIST TA,TOYOINTL ELECTRIC CHAIN HOIST HHBD,TRANSPORT BOOMER CHAINS,VAJ LEVER BLOCK,VL LEVER BLOCK TOYOINTL,WINCHLINE TAIL CHAINS,ZNL WIRE ROPE PULLING HOIST TOYOINTL